First steps: Investigating the feasibility of the processor/code.

As it happens, I had an Arduino Teensy left over from some exploration a couple of years ago.

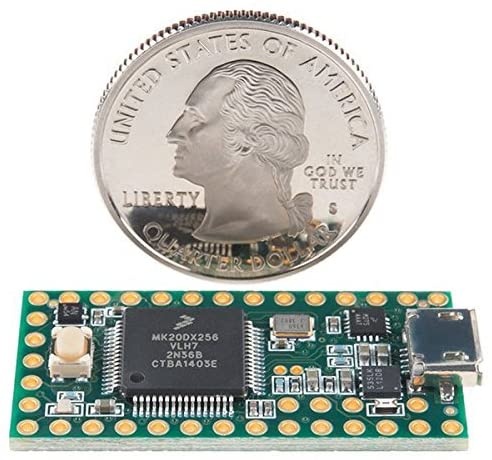

For those that don’t know it, it’s a tiny microprocessor about the size of the first joint of one’s thumb. I’ll flesh this out with more detail for those that are interested.

Microprocessors – essentially the tiny raw basics of a computer – are decades-old by now, but because they lack even the most rudimentary interface they’ve largely required expert knowledge to program. Today’s hobby microprocessors plug into your computer and are addressed via a downloadable software editor called an IDE, and while there is still some coding involved it’s lightyears more user-friendly than having to address it in its own language.

My exploration tells me the Teensy just happens to be the perfect device for this task (which is not entirely surprising, since I bought it for another midi related device project a couple of years back). It’s cheap ($40 CAD); it’s ubiquitous; there’s an enormous code base out there, and tons of examples to work from and public domain code from which to pillage and learn; it’s already a class-compliant-capable USB MIDI device out of the box so that’s a big task I won’t have to teach myself.

In fact, there’s an even cheaper version called a Teensy LC (for “low cost”) which runs around $25 Canadian, and I will be picking one up tomorrow to see if it will run the brief test code I’ve written on my Teensy 3.2. I don’t see any reason why it wouldn’t, as they’re almost the same, and the changes made to make it cheaper don’t really Impact the functions I am using. This will keep me from sacrificing my slightly more expensive Teensy 3.2 (and having to unsolder all of the header pins – ugh). I’ll keep the 3.2 as my workshop board.

Some microprocessors run at 5 volts, others run at 3.3 V, and some can handle both. The Teensy 3.2 runs at 3.3 V, and 5 V can kill it (not always, but my electronic skills are fairly rudimentary and I don’t think they’re up to making sure that I don’t).

This rules out a tiny 5V LCD screen I already had, but fortunately there’s a crop of new OLED micro displays that run at 3.3 V, and they are extremely crisp, bright and power efficient, and cost less than $8. In fact – if I scale up production to the point where I’m buying a half dozen or 10 at a time, they drop far lower than that.

Faders are relatively easy: I’m going for industry standard 100mm Bourns faders, 10k ohms. The technical diagrams say that they are 130mm long and there is 120 mm between the centers of the mounting holes, so that gives me useful layout information for minimum size of the box.

Now the single momentary pushbutton. My instinct says “metal” will be best, although at this point I can’t tell you exactly why. But soon, my own intuitions about the design of the box will become clearer to me.